Overall BESS quality has massively improved, but safety incidents make headlines

Panel moderator, Marija Maisch, Energy Storage News Director at pv magazine, opened the talk by simply asking each panelist to define BESS quality.

First up, Huawei’s Juan Carlos Mejia, a senior solution manager for the tech giant’s C&I Europe business, said BESS quality means safety, a good quality product or system, high usable energy capacity, long life cycle times, and streamlined operation. Multiuse management is key for higher revenues, Mejia added.

Neill Parkinson, product and business development manager for BESS at JinkoESS, agreed with Mejia’s point on streamlining. “Quality means holistic planning,” he said, adding that extensive auditing is required to ensure a project meets the standards of the country in which it is located.

Parkinson said he has been working in lithium iron phosphate battery (LFP) chemistry since 2007. He told the audience he believes LFP is the safest chemistry “for now”, and it is pushing out some of the other chemistries.

Kai-Philipp Kairies, CEO of battery intelligence company Accure, offered another perspective. Based in Aachen in Germany, Accure uses cloud computing to provide BESS-owners with safety insights.

“The energy storage industry is on a crazy exponential growth path,” said Kairies, adding that sometimes quality can be sacrificed for innovation.

Professionals need to ask themselves how they can make batteries safe from the get-go – i.e. with component selection, cells, and chemistry, said Parkinson. “You certify to worse-case scenario.”

Parkinson went on to explain the worst case scenario, also known as thermal runaway. “Contrary to popular belief, thermal runaway is not just fire. It’s not just the cascade… the thermal runaway itself is initiated within a single cell. And it’s the exponential self-heating on the single cell that drives the cascading fires that could occur.”

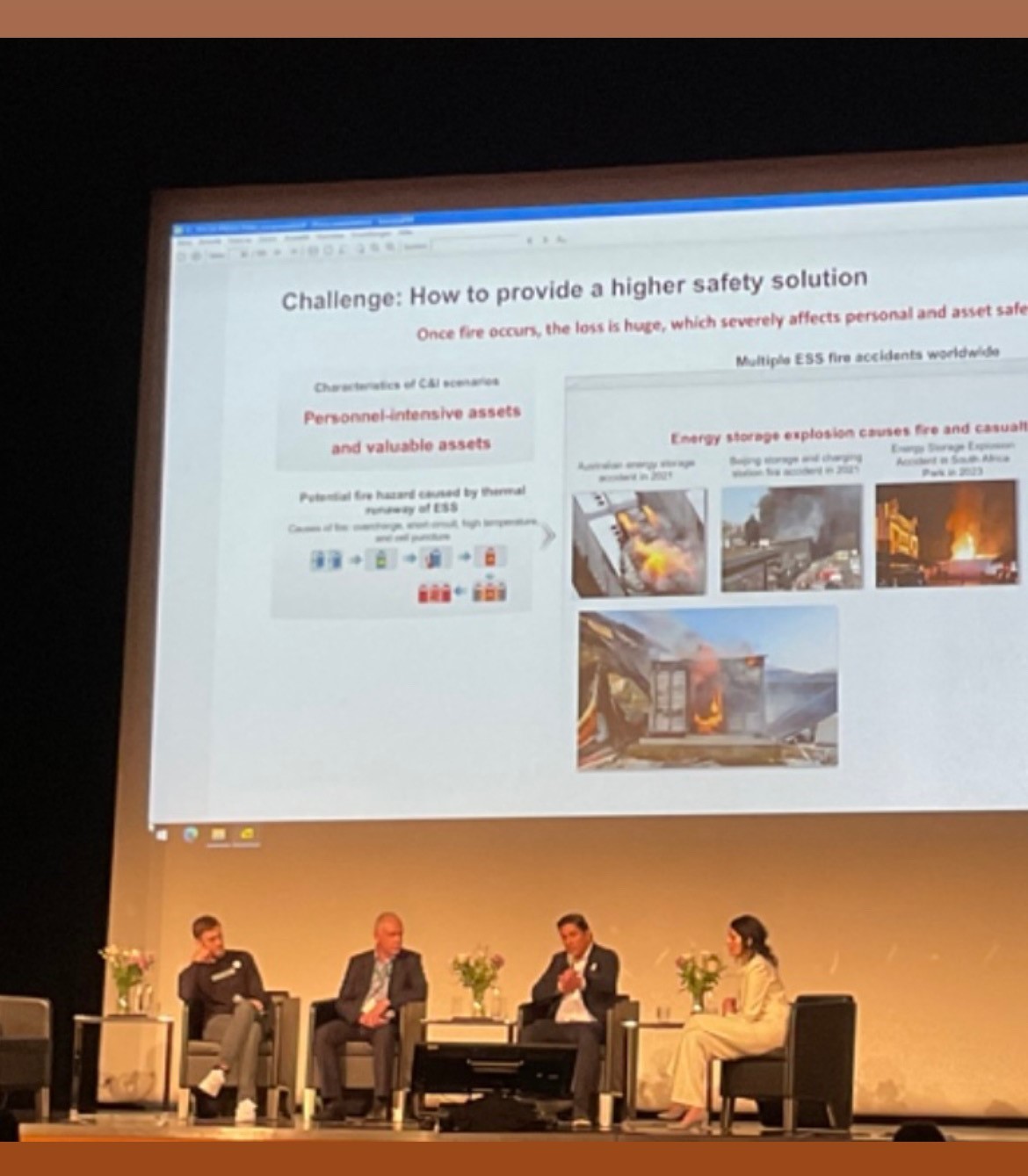

Mejia identified potential causes of thermal runaway as overcharging, high temperature, short circuit and cell puncture. “Our cell supplier EVE has decicated manufacturing lines only for us, that way we can best check quality and understand what we get into products,” he said.

Huawei’s Mejia went on to highlight the role of optimizers in BESS installations, saying that they can ensure that single modules are deactivated from a series in case of a safety incident.

For safety and quality, all reputable Tier 1 companies – JinkoESS is among their number – certify “well above” current standards, claimed Parkinson.

But this is not the case for everyone in the BESS sector, as Kairies sees in his work. “Of all the cells that are being produced today, mid-June 2024, over 50% of the cells come from immature production lines. They are less than two years old. And we know for a fact that in the first two years of commercial operation, there is more scrap, there’s higher spread in quality, and there’s more problems.

“At the same time, out of all the construction crews that go around commissioning batteries over half of them have less than two years of experience. So, we are in an industry where not only all the players change and all the technologies change but also just because of the sheer growth, we will always be in a learning curve for a big part of the market – and that’s where things break,” warned Kairies.

Even if BESS-owners have good certifications and processes, any failure outside of those is catastrophic. As Kairies pointed out, “That’s what gets you in the headlines.” He referenced a big San Diego fire that happened a few weeks prior at a 250 MW site owned by grid infrastructure developer LS Power. The fire burned for several days and reignited before it was eventually brought under control.

The panelists agreed that overall BESS quality has massively improved, but safety incidents are always going to be what people see. “I want this industry to be successful, but we need to be realistic,” said Kairies. “There will never be a perfectly safe car. People will die in car accidents as long as we have cars. There will be battery fires as long as we have batteries.”

The panel went on to highlight the vital role of good engineering. “We can not eliminate completely the risks, but we can mitigate as far as we can,” said Parkinson.

Listing the safety improvements that have been intergrated into the last-generation system, Mejia said that for him, the safety issue is sufficiently resolved and that focus should be laid on efficiency, lifetime, and use of systems.

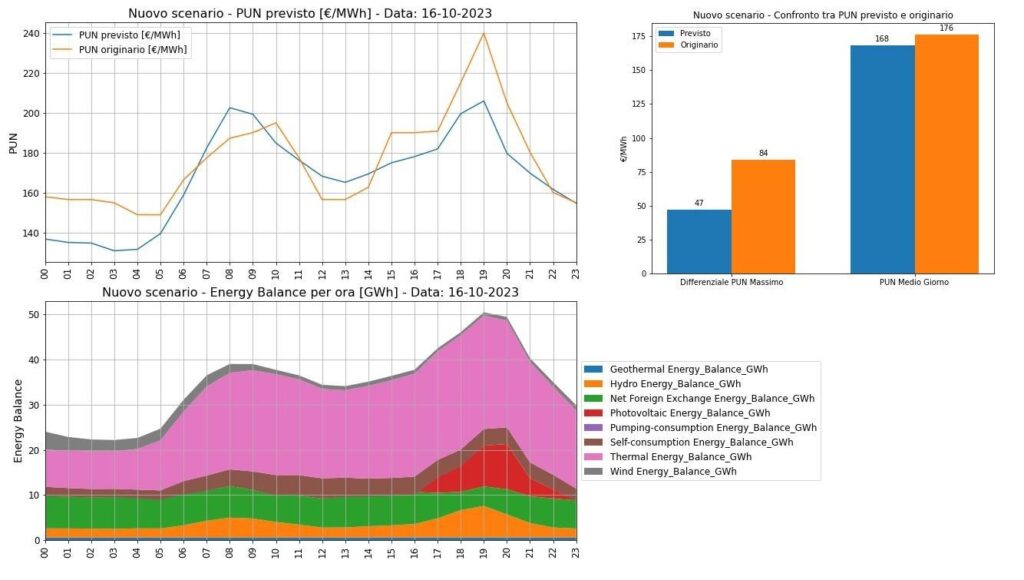

Mejia noted that there should be a standard of maximum 1.5 charge/discharge cycles a day and elaborated on the overall BESS business case. “LCOS is not a good parametar when we talk about BESS business case as it does not consider side costs related to grid connections. If we can build one relying on multiple revenue streams, that the cost of the battery system is not an issue at all,” he said.