Standard Energy unveils vanadium-ion battery with 1% degradation

South Korea-based Standard Energy has developed a battery with just 1% degradation after 20,000 testing cycles. The company uses vanadium-ion batteries (ViB).

It showcased the ViB at the recent Smart Energy Week in Tokyo. The company’s chief project and marketing officer, Gyucheol Lee, said that 10 years ago, the company was developing vanadium-redox flow batteries. However, this type of battery could never get above 80% roundtrip efficiency, as electric pumps were needed to move large amounts of electrolyte from tank to tank.

The company therefore shifted its focus to using vanadium in the same fashion as lithium – as an ion battery. Vanadium is an exciting candidate for cathode materials, Lee said, because it has many dispensable electrons in its atoms and features four ionic states. Multiple ionic states allow its electrons to move without the material changing from metal to ion state between charging and discharging. According to Lee, the change from metal to ion state promotes cathode-electrolyte-interphase growth – the principal degradation mode in lithium-ion batteries.

Only 1% degradation after 20,000 cycles

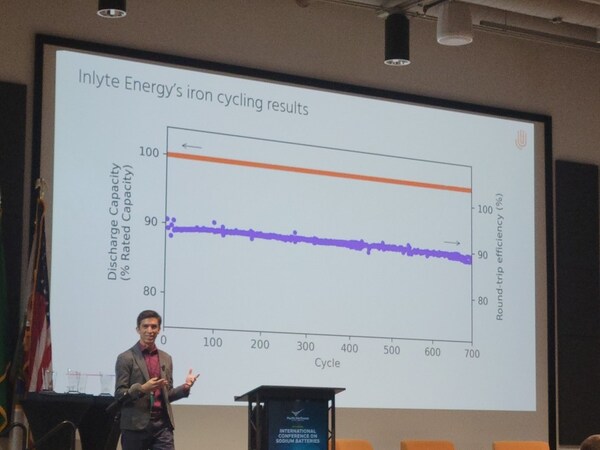

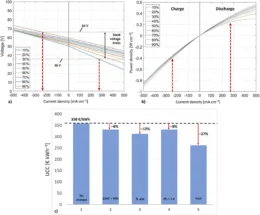

With no metal dissolution occurring in vanadium-ion batteries, the company has tested its batteries in its laboratory. Cycling them at a strenuous C-rate of 3, with 100% depth of discharge for 20,000 cycles, the company noted a degradation of just 1%.

In addition to this superior cycling life, the batteries are also said to be safer than their lithium-ion competitors. Standard Energy can use aqueous electrolytes in its batteries, rendering them virtually non-flammable. The current product also boasts a high-power delivery of a C-rate of 5, with a roundtrip efficiency of 96 %, according to test data.

High C-rates are only wanted sometimes. There are various requirements for energy and power delivery between different applications. Lee said vanadium-ion batteries do not require a change in cathode design, as with lithium-ion batteries – referring to the other use cases of LFP, NMC, and NCA batteries. Vanadium-ion batteries could be designed to deliver 10-hour duration storage for PV and wind systems or 5 C for UPS and frequency regulation without a change in their cathode design.

Some drawbacks exist

There are some drawbacks, however. Lee said vanadium is much heavier than lithium, making his batteries only usable in stationary applications, like large-scale battery energy storage systems (BESS) and residential storage systems.

Another issue is cost. At present, vanadium is very expensive. The price has risen 20-fold since the company started developing the product. With the startup-like production capacity and high resource prices, the batteries cost around double what competitively priced lithium-ion batteries cost.

Lee said he hopes the product will become more competitively priced when the company’s planned gigafactory starts operations in two years. He said he also thinks that vanadium prices could come down again. Vanadium is not scarce, with large quantities available in Australia, China, and South Korea. New mining projects could bring down the price of raw materials.

The company started selling its products in South Korea in December 2023. So far, it has sold 10 MWh of batteries. Standard Energy sells complete systems and helps project developers and engineering contractors with installation and system design. The company is now waiting for certification for use in Japanese grids. European certification could take another two to five years, but is now in the planning stage, said Lee.