Spanish initiative for advanced battery recycling technologies

Currently, the recycling rate of batteries varies depending on various factors, such as the recycling technology used, battery chemistry, and battery condition, among others. The new EU Battery Regulation, which went into effect in August 2023, sets very ambitious objectives regarding battery recycling. Specifically, it sets recovery targets of 50% for lithium and 90% for cobalt, nickel, and copper by 2028, which will increase to 80% and 95% respectively by 2031. In addition, it requires a recycling efficiency of 65% of the average mass of batteries by 2026 and 70% by 2031.

Today, the recovery percentage of cobalt, nickel, or copper ranges between 85% and 90% on the pilot scale. However, it is also necessary to achieve these recovery levels on the industrial scale. The current processes do not exceed 50% recycling efficiency as they do not take into account the recovery of many of components and focus mainly on the cathode.

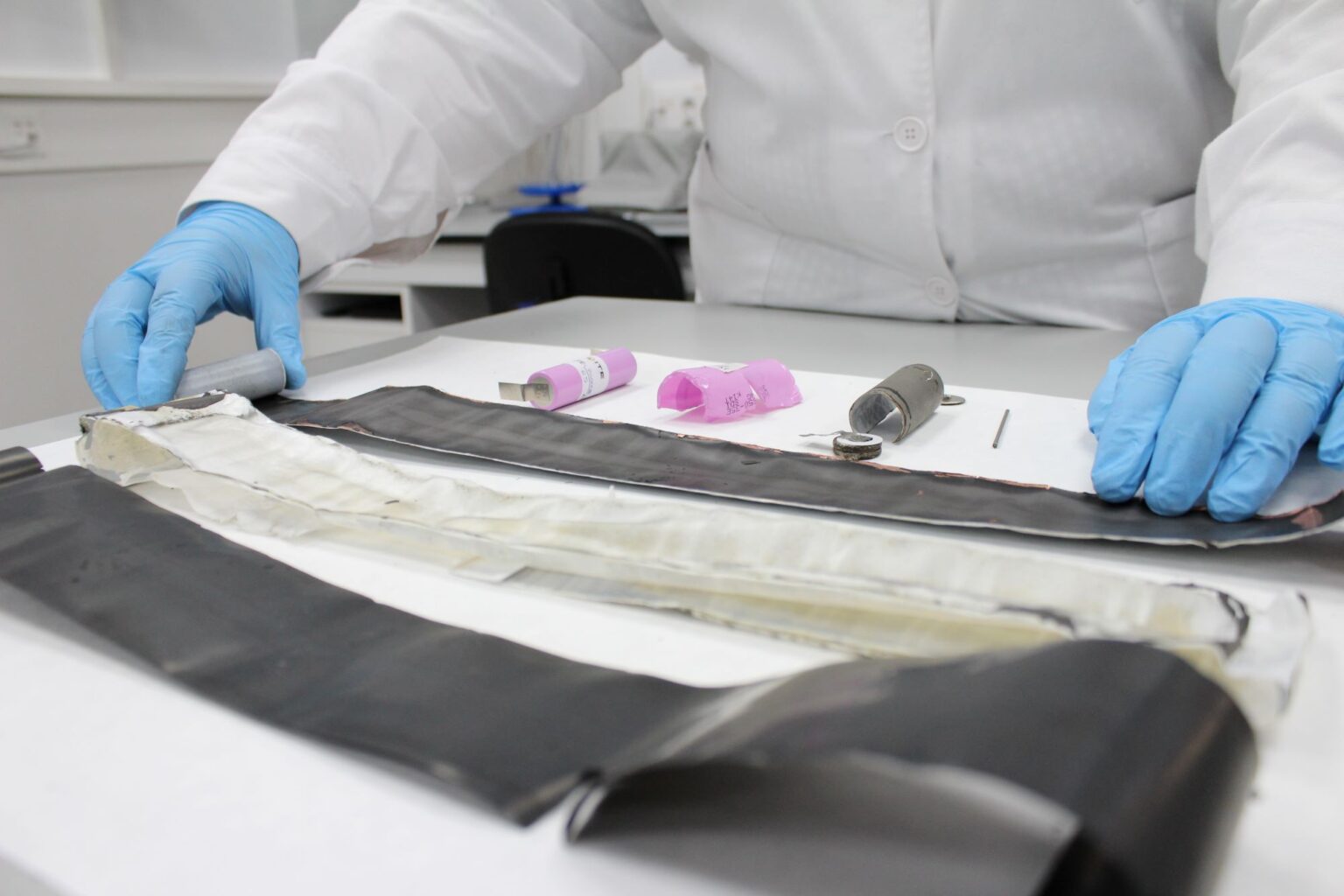

Therefore, the Energy Technology Institute has launched the RECILION project with the aim to develop a comprehensive process for the recycling of entire lithium ion battery cells. In a bid to maximize the efficiency and sustainability of this process, the project focuses on the development of innovative technologies for the separation and recovery of critical materials, as well as the evaluation of the quality and performance of recycled components in practical applications, such as the manufacture of new electrodes for batteries.

“RECILION’s goal is to develop advanced recycling technologies that are not only effective, but also reproducible on a commercial scale. Throughout the project, the aim is to generate deep and detailed knowledge about battery recycling processes,” Laura Cebrián, researcher and project manager, explains to pv magazine.

The aim is to investigate the complete recycling of the entire battery cell

The project aims to investigate the complete recycling of the entire battery cell, not just the most valuable materials found in the cathode. “We hope to achieve a selective recycling of graphite from the anode by implementing a strategy that efficiently eliminates the binder, thus improving the recovery rate. Also, we will implement electroleaching to recover cathode materials, which will be used as precursors for the synthesis of new cathodes, as well as the validation of all these recycled materials as components for batteries,” adds Cebrián.

The project will explore more sustainable and safer alternatives for the electrode delamination process, such as the use of deep eutectic solvents (DES) instead of conventional toxic solvents. Furthermore, novel techniques will be proposed – for instance, the use of supercritical fluids, such as carbon dioxide, to selectively remove the binder without damaging the graphite or other valuable components. Additionally, a low-temperature molten salt-based technology will be considered for the separation of cathode materials from current collectors, which promises to reduce energy consumption and operating costs associated with conventional thermal methods.

The new EU Battery Regulation stipulates that new batteries manufactured from 2031 onwards must contain at least 6% recycled lithium, 6% nickel, and 16% cobalt. These percentages increase to 12%, 15%, and 26%, respectively, by 2036.