SorbiForce uses agricultural waste to produce low-cost, safe batteries

US-based SorbiForce says it has designed its battery energy storage systems to be completely recyclable, reducing environmental impact and fostering a circular economy.

Its technology does not rely on fossil-based resources and instead utilizes agricultural by-products, like straw, and brine from desalination plants, making them a sustainable alternative to lithium-ion batteries.

The company uses its own ultra-porous carbon, water, and salt to develop its battery storage systems. It employs locally sourced raw materials that are abundant in most locations in the USA, thereby mitigating supply chain risks associated with traditional battery components.

According to SorbiForce, its battery is resistant to mechanical damage, non-flammable, non-explosive, has no problem with overcharging, requires no cooling, and has no thermal runaway. “The bromine salt ZnBr2 in our battery is used in firefighting,” the company says.

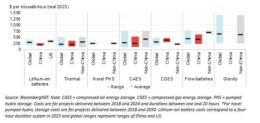

The cost of 1 kWh is 1.8 times lower than the price of 1 kWh on the lithium-ion battery market, the company claims.

At the end of their lifetime, the batteries can be easily disposed, fully recycled, and repurposed as organic compost, leaving minimal environmental impact.

The technology is touted as easily scalable offering a power range from 120 kW to 1 MW and storage capacity from 500 to 700 kWh.

The system measures 6 meters in length, 2.4 meters in width, 2.6 meters in height and weighs 18.9 tons.

The system needs four hours to charge and as much to discharge. SorbiForce guarantees 5,000 charge-discharge cycles and has a goal to extend this to 10,000.

“At present, we are introducing batteries with 4-hour and 12-hour cycles. That means 4 hours of charging/4 hours of discharging and 12 hours of charging/12 hours of discharging. However, we can manufacture batteries ranging from 30 minutes to 24 hours,” Serhii Kaminskyi, founder and CEO of SorbiForce, tells pv magazine Energy Storage. “We are focused on industrial applications for intraday operations.”

“Currently, the maximum gravimetric energy density is 64 Wh/kg. This is less than lithium-ion batteries but more than lead-acid batteries,” he adds. “For our potential customers, such as solar and wind power plants, data centers, utilities, nuclear power plants, and others, the specific energy density is not as critical as it is for portable electronics or electric vehicles.”

SorbiForce was founded in Arizona in 2022. It originates from Ukraine, where it established its R&D center in 2019. In that same year, it created a prototype with a specific energy density of 45-60 Wh/kg.

In 2020, the company created large prototypes weighing 0.7-1.5 kilograms suitable for scaling and operational through 1,000-plus cycles. A year later, it completed testing for 2 kWh battery system in a residential setting.

Last month, SorbiForce announced the closure of its crowdfunding campaign on Republic, raising $340,000 from 537 investors across 38 countries.

“This successful fundraising round not only validates the potential of our innovative technology but also underscores the urgent need for sustainable energy solutions. With this funding, we are well-positioned to accelerate our development efforts and bring our groundbreaking battery technology to market,” said Serhii Kaminskyi, founder and CEO of SorbiForce.

The funds raised will enable SorbiForce to continue patenting and begin the certification process, optimize manufacturing processes, expand its expert team, and scale production, the company said.