Thermal energy storage tech to bolster industry decarbonisation in Australia

Thermal energy storage system (TESS) developer MGA Thermal based in New South Wales, Australia, will take steps to scale up their renewable energy generator to commercial deployment after receiving $2.48 million (USD 1.6 million) in a second round of funding from the Australian Renewable Energy Agency (ARENA).

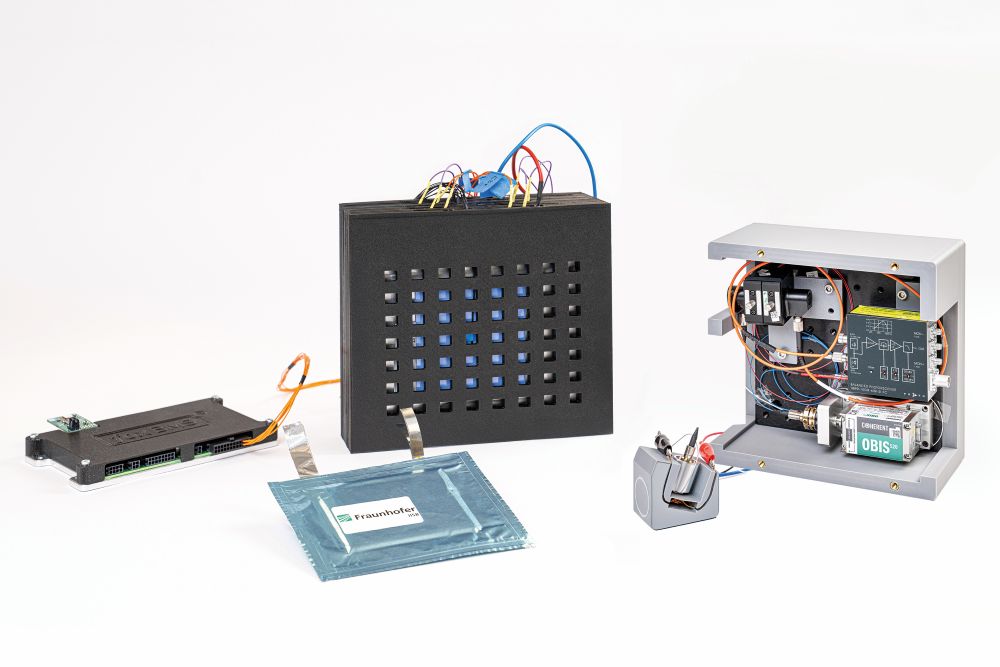

The initial round kick-started the MGA Thermal Energy Storage Project in 2022, to design, manufacture and operate a 0.5 MW thermal demonstration-scale TESS using the company’s proprietary Miscibility Gap Alloy (MGA) technology.

The final product has a planned storage capacity of 5 MWh and will demonstrate charging and discharging of up to 500 kW.

We believe MGA Thermal will play a key role in enabling renewable generation.

MGA Thermal Chief Executive Officer Mark Croudace said the world’s industrial sector is at a critical juncture in its renewable energy, decarbonisation journey and the funding will help the company recommission the demonstrator and scale up for commercial deployment.

“We believe MGA Thermal will play a key role in enabling renewable generation to meet the industrial sector’s needs. A behind-the-meter energy storage solution that helps balance utility-scale renewables with distributed energy storage is vital for Australia to effectively manage the evolving supply-demand dynamics of a clean energy future,” Croudace said.

ARENA Chief Executive Officer Darren Miller said ARENA is committed to supporting companies with solutions for the country’s energy transition.

“We prioritise projects with enduring impact and see the value in MGA Thermal’s technology for assisting large industrial players in decarbonising their processes.”

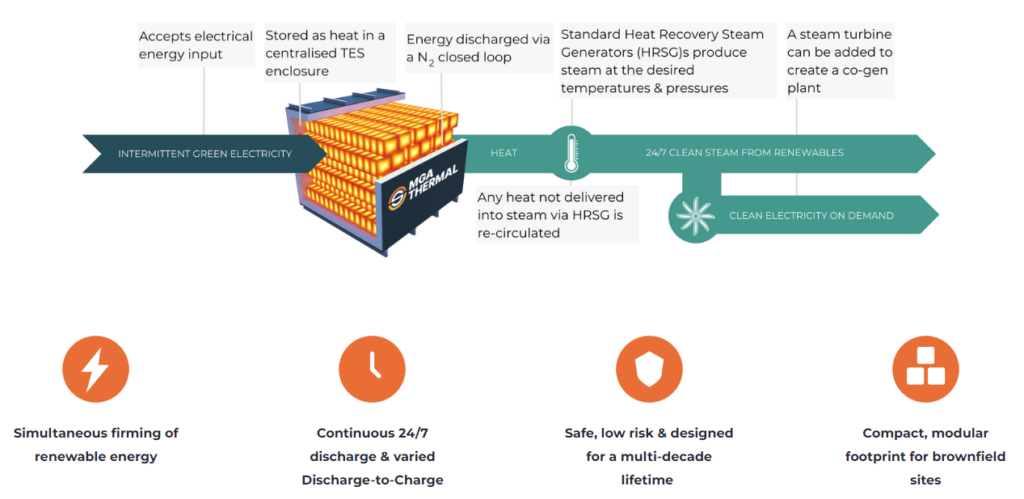

By storing and dispatching heat energy in the form of clean steam, MGA Thermal aims to offer sustainable alternatives to fossil fuel-dependent processes and complement current renewable solutions with behind-the-meter options to capture off-peak energy and optimise energy efficiency.

The steam-dispatch thermal energy storage technology consists of small particles of an alloy embedded within graphite-based blocks which are enclosed within a fully insulated system. Electrical heating elements superheat the alloy to an operating temperature of 400-700℃, while the graphite matrix contains the molten alloy.

Heat storage for hours and even days

The blocks store heat for periods ranging from hours to days with minimal loss of energy. Heat exchangers use a transfer gas to absorb heat from the MGA blocks, with the heated gas or fluid suitable for industrial heat applications or to drive a steam turbine to generate electricity.

The demonstrator is hoped will have application in industrial process heating, waste heat capture, and for use in mid to long-term firming of grid-scale electricity generation from renewable energy sources.

Data from the demonstrator will cover the charging and discharging behaviour, fluid dynamics and temperature distributions, and validate the efficacy of mid-to-long-term thermal storage in a practical system.