Energy-storing carbon fibre composites pave the way to weightless batteries

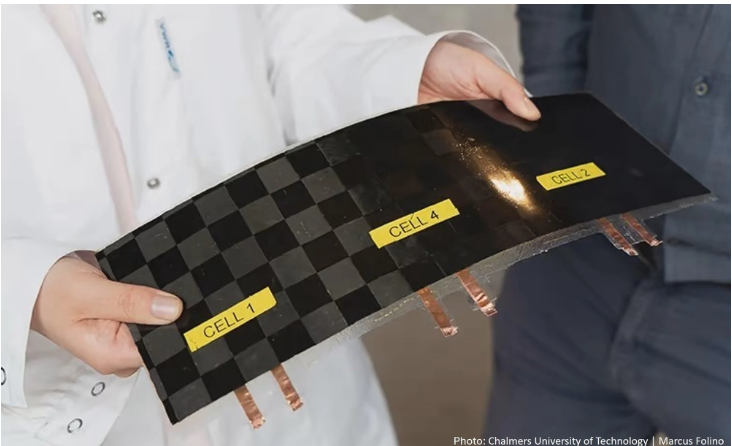

Sinonus, a spin-out from Chalmers Technical University (CTU) in Sweden, has developed a unique carbon fiber material that can store electrical energy, enabling energy storage in existing structures for a variety of industries – from electric vehicles and airplanes to wind turbine blades.

The company was founded in 2022, a year after CTU researchers found a way to apply their carbon fibre composites to the real-world applications. Presently, Sinonus says it is on the cusp of commercializing its technology.

“Sinonus has developed an amazing carbon fiber composite that doubles as a battery,” Markus Zetterström, wrote on LinkedIn as he accepted the role of the company’s CEO a month ago. “By substituting part of the structural material in systems/applications to our multipurpose composite, it’s possible to add electrical storage capacity at sustained weight and volume, or to decrease system weight and volume at sustained battery capacity (and of course some combination thereof).”

The energy density of the material is dependent on the required structural and electrical properties of the application.

“One might say that the higher the structural needs/specifications are, the lower the energy density becomes (and the other way around). While keeping a good structural capacity the possible span of energy density is around 25-50% of a conventional lithium-ion battery at current technology level,” Zetterström tells ESS News.

Sinonus has already demonstrated the technology’s potential by replacing AAA batteries in low-power products in its lab. Its goal is to expand the technology to larger applications such as IoT devices, and eventually to drones, computers, larger vehicles, and even airplanes.

The carbon fiber technology in Sinonus originates from Oxeon, another Chalmers Venture’s portfolio company. The carbon fiber was used in the propeller blades for NASA’s Ingenuity helicopter on Mars, chosen by the engineering team due to their ultralight weight and thinness.

The development of structural batteries at CUT has proceeded through many years of research, including previous discoveries involving certain types of carbon fiber.

According to a CTU study from 2018, the introduction of carbon fiber-based structural batteries showed potential for a significant weight-reduction in the aircraft and vehicles.

Leif Asp, CTU Professor of Material and Computational Mechanics, led the research into the ability of carbon fibres to store energy rather than simply to act as a reinforcing material. Asp and his team found structural batteries could reduce the weight of cars and aircrafts by up to 50%.

“Structural batteries may perhaps not become as efficient as traditional batteries, but since they have a structural load-bearing capability, very large gains can be made at system level,” Asp said at the time of research publication. “In addition, the lower energy density of structural batteries would make them safer than standard batteries, especially as they would also not contain any volatile substances.”

In 2021, CTU researchers reached another milestone announcing a structural battery that performs ten times better than all previous versions. It contained carbon fiber that serves simultaneously as an electrode, conductor, and load-bearing material.

The battery had an energy density of 24 Wh/kg, meaning approximately 20% capacity compared to comparable lithium-ion batteries available at the time.

“Previous attempts to make structural batteries have resulted in cells with either good mechanical properties, or good electrical properties. But here, using carbon fibre, we have succeeded in designing a structural battery with both competitive energy storage capacity and rigidity,” said Asp, leader of the project.