Australian grid-scale battery supplier gets $2m for electrolyte production

Brisbane-headquartered grid-scale battery assembler Energy Storage Industries (ESI) Asia Pacific has received an AUD 3 million ($2.02 million) grant from the Queensland Department of State Development and Infrastructure’s Regional Economic Futures Fund (REFF).

The new round of funding has seen ESI enter a partnership with Townsville-based Cleveland Bay Chemical Company to help increase ESI’s iron flow electrolyte production from 3 million liters per year to 43 million liters per annum.

The funds will support an upgrade of ESI’s battery-grade ferrous chloride plant in Townsville, which will improve production and laboratory facilities, to develop what the company hopes will be the most advanced facility in the North Queensland region supporting the chemical production needed for long-duration energy storage using iron flow battery technology.

Part of the funding will also be used by the ESI and Cleveland Bay to conduct a concept study into the potential for building a commercial chlor-alkali chemical plant that would produce hydrochloric acid and other reagents used for refining and processing critical minerals.

ESS supply deal

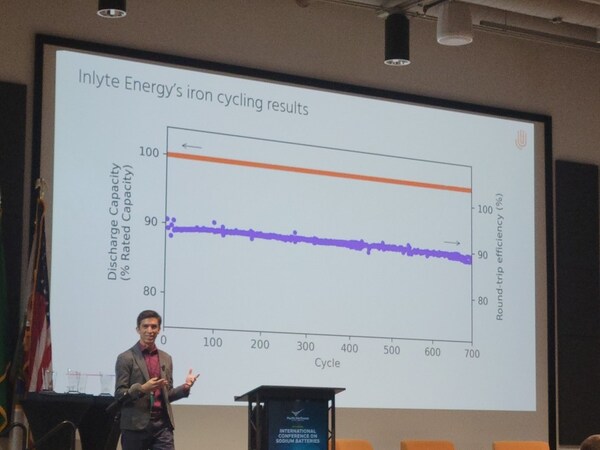

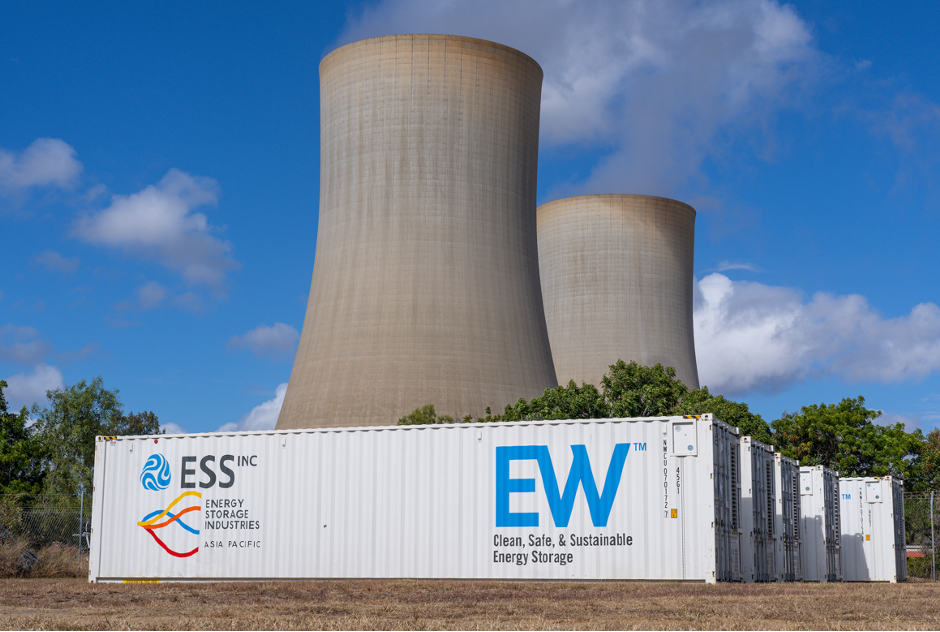

ESI signed a strategic agreement with US-based iron-flow battery company ESS Inc., in August 2022, which committed the Australian business to construct a plant in Queensland to assemble iron-flow batteries using ESS components. At the time, the aim was to produce batteries from 2024 onwards with ESS stating the battery plant would rise to an eventual annual production capacity of 400 MW.

ESI Asia Pacific Managing Director Stuart Parry, who in 2022 had highlighted ESI’s ability to locally source electrolytes, said the latest support, from the REFF, would enhance Australia’s energy security and create skilled jobs and economic opportunities.

“We’re excited that our partnership with Cleveland Bay Chemical Company will expand production of Australia’s first iron-based electrolyte made for commercial batteries,” Parry said. “Crucially, we’re strengthening the resilience of the supply chain for iron flow batteries and supporting the development of a critical minerals supply chain as we improve energy security for all Australians.”

ESI has begun construction of the large-scale iron flow battery manufacturing plant at Maryborough, 260 km north of Brisbane.

Other awards from the AUD 200 million REFF funding round included AUD 500,000 for the Queensland Resources Council to determine the viability and connection costs of using post-mining land for potential renewable energy projects across the Bowen Basin, in Central Queensland.

From pv magazine Australia.