LG Energy Solution announces substantial ESS revenue growth, new products

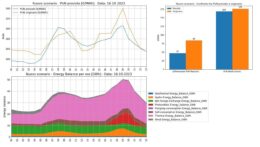

LG Energy Solution (LGES) announced on Monday its third-quarter 2024 consolidated revenue of KRW 22.18 trillion ($323 million) and an operating profit of KRW 751.9 billion, including the estimated IRA tax credit amount of KRW 466 billion.

While it has seen a 39% drop in profit from last year amid a sluggish demand for electric vehicles, the South Korean battery heavyweight has reported a considerable increase in energy storage revenue, particularly in the grid-scale market segment.

“Expanded sales to major European automakers and increased production at our joint venture facilities in North America and Indonesia, as well as substantial ESS revenue growth from grid-scale projects, improved the overall revenue compared to the previous quarter,” said Chang Sil Lee, CFO of LGES.

According to Lee, LGES also saw quarter-on-quarter improvements in the operating profit, excluding the IRA tax credit’s effect “on the back of improved utilization rate led by shipment increase in both EV and ESS batteries, as well as reduced unit cost burden in line with metal price stabilization.”

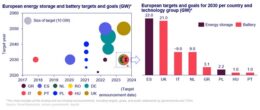

The company said that it expects “strong demand momentum,” especially in power grid applications. Its plan is to actively respond to “long-term, large-volume projects in North America, leveraging its stable production know-how and local supply capability, creating opportunities to generate stable revenue.”

“To maximize the benefits from policies supporting local manufacturing, the company will start ESS battery production in the U.S. next year and also consider converting EV production lines to ESS in response to the European market demand,” the company said in the announcement.

The announcement comes after, earlier this year, the manufacturer paused the construction of a battery production line for energy storage systems at its multi-billion dollar battery factory in the US state of Arizona. While it said that the buildout of its EV cell production plant was continuing as planned, it described the move as adjusting the pace of planned investment execution according to market conditions.

When fully operational, the Arizona complex’s average annual production capacity is expected to reach 53 GWh (cylindrical batteries 36 GWh, LFP ESS batteries 17 GWh).

LGES has another standalone facility in Michigan, which was built a decade ago and is undergoing expansion that would quintuple its average annual production capacity. The company also has five other joint venture facilities in the US with major automakers, including General Motors, Honda, and Hyundai Motors Group, representing its full-fledged efforts to provide IRA-compliant batteries to its local cuctomers.

New products and services

To improve its competitiveness in the hot market, LGES is planning to launch high capacity LFP ESS batteries with energy density improved by 20%.

The South Korean manufacturer has also long been faithful to nickel manganese cobalt chemistry in energy storage products and has initiated its move to today’s industry standard LFP back in 2022. The move to the safer nickel and cobalt-free battery chemistry followed LGES’ forced recall of some of its battery energy storage systems in the United States and Australia due to potential fire-related risks.

Furthermore, LGES said it is readying to launch advanced energy management and system integration software. The battery management business will operate under a new brand – B.around – and also offer an advanced safety and degradation diagnostic solution.

Meanwhile, with the initiation of its integrated management business, LGES aims to set the groundwork for entering the independent power producer space with energy storage plants.