Concentrated solar power: much cheaper than batteries for energy storage

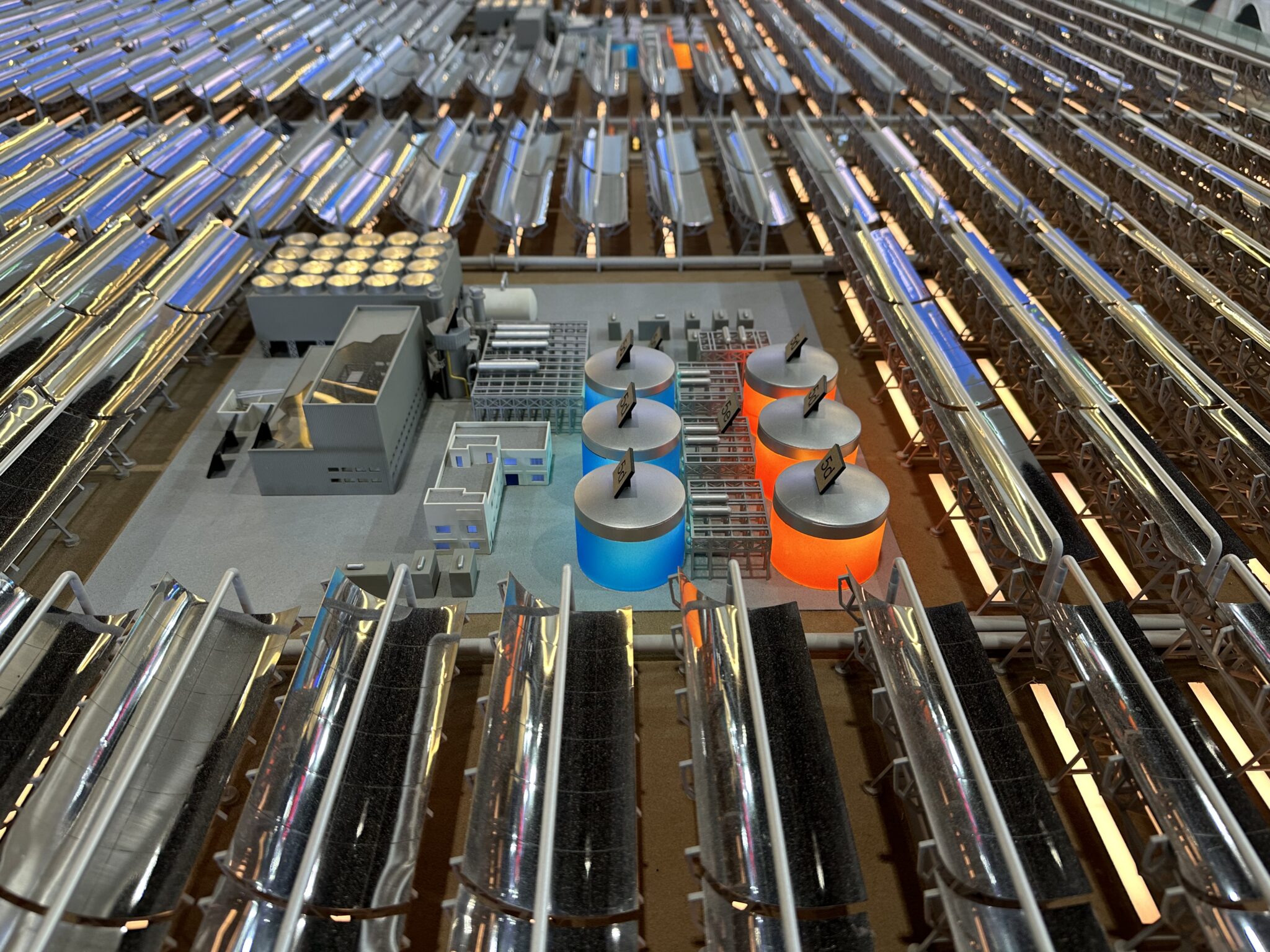

Solar thermal energy, otherwise called CSP, is a renewable energy that uses the heat of the sun collected by various types of focusing mirrors. The energy from the concentrated sunlight heats a high-temperature fluid in a receiver, goes to a heat exchanger, and finally drives a steam or gas turbine to produce electricity.

A very promising renewable energy source in the first decade of the 21st century, the market for CSP has, however, failed to really take off in recent years, and while several plants are being built around the world, most notably in China, prices have not come down sufficiently to make it economically viable. Building and maintaining concentrating solar collector fields in harsh, often desert conditions is too often more expensive than other forms of renewable energy, such as photovoltaic energy and wind power.

Storing energy cheaply

“The competition from … PV has taken market share away from the more complex solar thermal technology because the prices of solar panels have come down so much over the last 15 years and they are so easy to install. [They are] literally ‘plug and play.’ Solar thermal, however, has an important advantage over … PV: cheap energy storage,” said Eckhard Lüpfert, the chair of IEC [International Electrotechnical Commission] TC 117, the IEC committee which prepares standards for solar thermal electric plants.

The typical thermal storage system consists of insulated storage vessels filled with hot molten salt, plus pumps and heat exchangers. Lüpfert said the price of thermal storage is much cheaper than lithium-ion batteries, which are currently one of the most used forms of energy storage. “The performance of batteries is improving but thermal energy storage has an important edge and is still about a hundred times less expensive,” said Lüpfert.

An article published on the Science Direct website stressed that “in areas with a high solar resource, CSP can play a crucial role, thus, significant advances are being made to increase its competitiveness through the improvement of the energy storage systems integrated with CSP”. The paper highlighted the potential of CSP thermal energy storage to stabilize the grid by “being able to generate power during hours of high demand (high price periods [during] morning and evening), and to store energy efficiently when electricity demand is low but renewable energy is available in excess (low price periods, [at] midday).” The idea is for CSP to combine with other renewables, such as PV, and to provide grid-scale energy storage. To find out more about the different energy storage systems and technology used in CSP, read here.

Industrial process heat

Another selling point for CSP is its use in industries relying on a large amount of energy for heating processes, generally described as industrial process heat. This includes petroleum refining, chemical production, iron and steel manufacture, cement, and the food and beverage industries.

To make cement, for instance, raw materials such as limestone and clay are ground to a fine powder which is then heated to a temperature of 1,450 C in a cement kiln. The heating process relies on energy from fossil fuels, which are huge carbon emitters. Pressure is mounting from all corners for the cement industry to decarbonize. While some research is focusing on materials that will require less heating, the concentrated sunlight used to heat transfer fluids in CSP can be employed to provide the high temperatures needed in cement production.

CSP can also be used for solar-powered fuel production, a subject which is drawing increasing interest. To find out more about this, read: Understanding solar-made fuels | IEC e-tech.

Need for standards

IEC TC 117 published its first standards in 2017 and has developed key benchmarks for the industry in recent years, all of which are crucial to stabilize the quality of components and installations and to help bring down the cost of CSP technology, making it more competitive. Standards also ensure the safety and reliability of CSP systems used around the world. “A CSP plant is not only an electrical installation, it’s almost a chemicals process plant,” said IEC TC 117 chair Lüpfert. “It deals with hazardous materials such as organic fluids, which are heated at very high temperatures. Ensuring the safety of workers and the plant’s surrounding environment is, therefore, of paramount importance and one of the key focuses for our standards.”

Looking towards the future, another area standards will be required for is precisely linked to the use of CSP for niche applications, such as industrial process heat. Lüpfert said, “We can apply the learnings and achievements of STE [solar thermal energy] plants and apply them to process-heat industrial applications. We need to broaden the applications of TC 117 standards. It is often a matter of scaling down what we have already achieved, in terms of performance and reliability.”

One of the main challenges will be to attract the right kind of experts to take part in standardization work. “We have many scientists and researchers but we need more people who are involved on the ground, and experts from industry,” said Lüpfert.

There is hope. “Since Covid, we have changed our ways of working and meeting online has been a blessing,” added Lüpfert. “Thanks to online tools, we have started to attract people who are better qualified for the work we need, notably from the industrial sector. We also use forums like SolarPACES, a technology collaboration platform which enables us to discuss pressing issues relating to CSP, before having the formal constraints of standardization.”

As the race to meet zero carbon emission targets accelerates, CSP technology can play an important part in ensuring we get there, with the help of IEC international standards.

By Catherine Bischofberger

The IEC is a global not-for-profit membership organization bringing together 174 countries and coordinating the work of 30,000 experts. IEC international standards and conformity assessments underpin international trade in electrical and electronic goods. They facilitate electricity access and verify the safety, performance, and interoperability of electric and electronic devices and systems, including, for example, consumer devices such as mobile phones and refrigerators, office and medical equipment, information technology hardware, electricity generation equipment, and much more.